Our engineered hardwood flooring is made from sustainably-sourced European Oak with a UV oil finish, enhanced with an additional hybrid protective layer.

An engineered wood floor is a type of flooring that is made from real wood, but it differs from solid hardwood flooring in its construction. Engineered wood flooring is designed to provide the appearance and warmth of traditional hardwood while offering increased stability and resistance to environmental factors like moisture and temperature changes.

Layered Construction: Engineered wood consists of multiple layers of wood. The top layer, known as the wear layer, is made of real hardwood. At WFI our top layer is made of oak providing the visual appeal and texture of natural wood.

Core Layers: Beneath the top hardwood layer, there are several core layers. These core layers are made of plywood. The core layers are often arranged in a crisscross or perpendicular pattern to enhance the floor's stability and strength.

Enhanced Durability: The layered construction of engineered wood adds to its durability. It is less prone to warping, cupping, or expanding and contracting with changes in humidity and temperature compared to solid hardwood flooring. This makes it a suitable choice for areas with variable climate conditions.

Versatility: Engineered wood flooring is available in a wide range of colours and patterns of plank, herringbone and chevron. This diversity allows homeowners to choose a floor that matches their interior design preferences.

Ease of Installation: Our engineered flooring comes in a tongue-and-groove installation system, making it easier for DIY installations. It can be installed as a floating floor (not directly attached to the subfloor), glued down, or nailed down, depending on the specific product.

Cost-Effective: Engineered wood flooring is more budget-friendly than solid hardwood, making it an attractive option for those who want the beauty of wood flooring without the premium cost.

In summary, engineered wood flooring offers the aesthetic appeal of real wood with added durability and stability due to its layered construction. It has become a popular choice for flooring in a variety of settings, offering a balance between the elegance of hardwood and the practicality of engineered design.

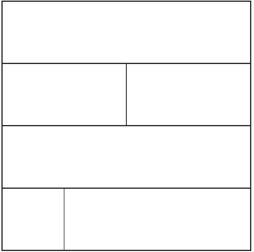

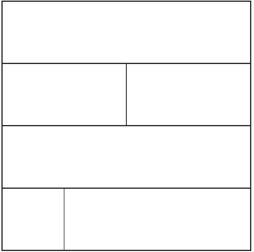

The plank design is a classic form of wooden floor. The flooring is traditionally laid in a staggered pattern where the planks are arranged on alternating sides of a centre line so that the seams appear to be random, which gives the floor a fluid and uniform look.

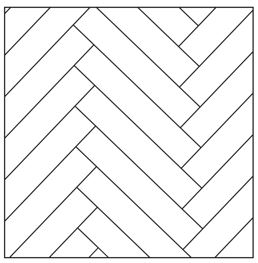

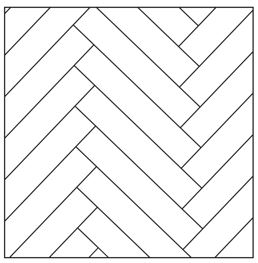

A herringbone floor is made with small rectangular planks all cut to the same size. Each plank is laid out at a 90-degree angle from another, creating a broken zig-zag pattern that is prized for its asymmetry. A Herringbone floor has a great deal of visual movement and can help to make smaller spaces seem larger.

The chevron design utilises a zig-zag pattern that is similar to Herringbone. However, rather than being laid in a staggered pattern, they are more uniform and are laid to form a true centre point. The regularity of Chevron style flooring means it creates a simple and cleaner appearance.

One of the most frequently asked questions! The difference is all in the zigzag, where Chevron patterns have a continuous zigzag design whereas the Herringbone pattern has a broken zigzag design.

A wear layer is part of an engineered wooden floor. It is the top layer of the plank of flooring which is seen once installed giving it it’s authentic wood look.

There are 3 plank widths available – 125mm, 190mm and 240mm.

Herringbone boards come in a 120mm width.

Chevron boards come in a 120mm width.

Krono Swiss laminate flooring consists of an engineered wood-based core board made of wood from sustainably managed forests and a decorative layer.

Laminate consists of approximately 90% wood fibers and approximately 10% environmentally friendly adhesive resin.

Krono Swiss laminate has been certified with the Blue Angel, the Swiss federal government's eco-label. Floor coverings do not contain plasticizers, pesticides or other harmful additives. You can be sure that Krono Swiss laminate is a non-hazardous and environmentally friendly product.

Our Krono Swiss laminate flooring is available in 3 thicknesses; 8mm, 10mm & 12mm.

At Wood Flooring Ireland, all our hardwood flooring is made to order for each customer at our in-house production facility. For this reason, please allow approximately 6 weeks for your order to be produced and delivered. A member of our team will be in touch regarding your delivery.

Note: All production times given are approximate only and while normally correct, are subject to change without notice.

Hardwood:

Once your flooring has been produced, a member of our team will be in touch regarding your delivery. Delivery is usually 2-3 working days.

Laminate:

For all laminate flooring, orders will be dispatched within 2-3 working days.

Yes, once your order has been produced, our team will be in touch about your delivery.

Please ensure the phone number you have provided is the best number to contact you on. All of our standard delivery services will be between 9am-5pm Monday to Friday.

The flooring we deliver is generally heavy, our delivery service is ‘kerb side’ due to insurance guidelines, so please arrange for adequate help to move your delivery inside.'

Please ensure that you inspect the goods immediately upon delivery. In the unlikely event that your goods are damaged on delivery please let the delivery driver know. Please note that no claim for damage can be entertained once the delivery driver has left the delivery address, therefore it is very important that you check the delivery once received.

Delivery charges depend on the weight and dimensions of the order and the location, this will be calculated at the checkout.

No, we do not deliver to the UK at the moment.

We accept a wide range of payment methods online. All Visa, Mastercard, Maestro and American Express debit/credit cards accepted. Paypal, Stripe and Apple Pay options are also accepted.

Yes, we do offer finance options depending on the order value and the products you are ordering, approval is subject to status. This finance option is provided by Humm. There is no deposit required, and most applications are approved instantly via our online order system. Any queries on Humm please visit, https://www.shophumm.com/ie/how-it-works/

No, as a manufacturer, we do not offer an installation service. Please ensure that the person installing your hardwood or laminate floor is a suitably qualified fitter.

Here is a guide from our laminate manufacturers:

https://www.swisskrono.com/ch-en/products/flooring/laminate-guide/laying-instructions/#/

You can order up to 3 wood flooring samples and/or 3 laminate flooring samples, free of charge.

There is a postage fee of €5 for sample orders.

Wood samples are useful for comparing colours and finishes. However, as wood is a natural material, no two pieces are identical and variations can arise between batches. Differences in colour, grain, knots, and texture are inherent due to its natural properties. Therefore, these samples may not represent the exact appearance of the finished floor.

Please note, these 190mm samples may not represent the actual width of the product you decide to purchase.

The hardwood floors produced by Wood Flooring Ireland are sourced from sustainable forests throughout Europe. They are hand-stained with a matt lacquered finish and come in a variety of colours.

We recommend using special cleaning and maintenance products to keep your hardwood floors in pristine condition. See our Care Kits to find the right home care kit for your flooring.

We do not recommend cleaning lacquered, hardwood floors with a wet mop – excess water may cause the floor to swell, warp or discolour.

We do not recommend using wax, soap, or any other household cleaners on lacquered, hardwood floors as they may dull the floor’s finish.

We advise that you do not let sand, dirt, or grit build-up on the surface of your floor, as this can cause abrasions that will dull the hardwood finish.

We recommend that you vacuum or sweep your floors regularly (at least once a week is advisable).

We recommend putting down mats at exterior doors to trap excess sand and grit. Using rugs in high traffic areas, at the end of stairs and near doorways is advisable. However, avoid rubber backed or non-ventilated rugs.

We recommend using protective pads or caps on the legs of furniture and to keep your pets claws trimmed to avoid scratches and gouges in the hardwood.

Remove any dust, and dirt with a broom or vacuum cleaner suitable for hard surfaces. A thorough cleaning is then recommended to get rid of any dirt residues which might linger. The floor can be cleaned with a wet mop, battery powered jet mop cleaner. If using a traditional mop, use a suitable “hard surface” cleaner diluted in water. Do not use any cleaning agents containing wax, oil or polish, which can form a dull film that will reduce the appearance and performance of your floor.

Cleaning of stubborn stains:

An alcohol-based cleaner can be used for difficult stains but should be applied to a cleaning cloth and not directly on the floor, and the affected area should be cleaned afterwards with water.

Please note:

Do not use abrasive cleaning pads, sponges and cloths, or scourers, etc. Do not sand, varnish or wax your Krono Swiss laminate flooring.

Following these simple instructions will ensure that your floor remains beautiful for a lifetime!

Please see our easy to follow measuring guide here

If you don’t see an answer to your query in the FAQs provided, you can email us on info@woodflooringireland.ie and we will do our best to help you with your query.